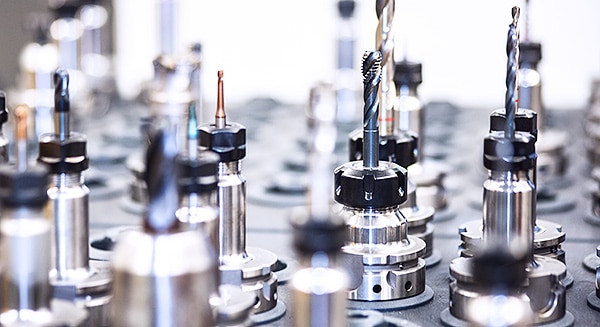

At the beginning of every injection molded part is the mold construction – i.e. the production of the mold, the

represents the basis of the respective plastic part to be manufactured. To produce complex injection molded parts

with absolute repeatability and tight tolerances requires a high degree of precision.

it a high degree of precision with regard to mold construction. Our mold makers from

LÖSCH work with a lot of experience in the field of parts manufacturing and are at your disposal for advice with know-how. In this way, we ensure that your desired plastic injection molded parts are steered into the right shapes right from the start.

Our experienced team offers you a wide range of services in the field of plastic and silicone mold making as well as tooling – always precisely tailored to your wishes and needs. We support you in all necessary steps up to the finished product. Whether project planning, checking the feasibility of the design or putting the final touches to the construction: In the end, you hold your perfect molded part from LÖSCH in your hands.