LÖSCH is your injection moulded liquid silicone rubber expert. Drawing on our experience from the millions of injection moulded parts we have produced, we manufacture, produce and improve your silicone piece for a variety of applications. We support our customers from idea to product and process development, all the way to industrial production.

Our high quality standard ensures each and every part is identical.

Our silicone experts help you choose a material suitable for your product and its requirements.

Injection Moulded Liquid Silicone Rubber (LSR)

Silicone injection moulding is our passion

MILLIONS of injection moulded parts from liquid silicone rubber are the basis for our know-how

Silicone moulded parts for the industry

Automotive, energy, electrical engineering, food, medical and aerospace industry: The requirements vary from industry to industry.

Our finished silicone parts are more than just precision parts.

We produce high quality moulded silicone parts with different properties, looks and a good feel – from prototypes to small and large-scale series.

Why liquid silicone rubber?

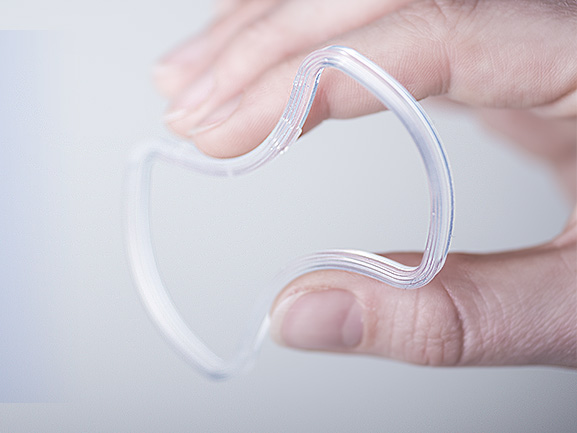

Liquid silicone rubber (OLSR) injection moulded parts are very pliable, odourless and tasteless, chemical-, UV- and temperature-resistant, and non-ageing. Mastering the process opens up many applications. And our system solutions provide you with the best basis. We know how.

A precision part is only as good as the tool

Our in-house mould design and production guarantee a fast track, quick response times and timely delivery of all LSR injection moulded products.

We’re flexible

Parts examples

Plastics Injection Moulding

LÖSCH has extensive experience with all types of plastics and their processing methods. We produce precision parts with tight tolerances, in large quantities and complex shapes. And our system solutions provide you with the best basis.

Optical Grade Silicone

Optically clear LSR (liquid silicone rubber) has virtually the identical transparency as glass, combined with the advantages of silicone. Of course optical grade silicone is one of the manufacturing processes we offer. We will gladly advise you.

ISO 9001 certified

Our quality standards go beyond standard certifications.

In-house mould making

Our in-house mould making provides us with the highest flexibility and maximum shape accuracy.

Everything from one source

One contact point, one responsible party. So we are always on time and deliver the highest quality.

Injection Moulded Liquid Silicone Rubber FAQ

How small can liquid silicone injection moulded parts be?

Precision moulded parts, including micro-injected moulding, are not a problem for us. At LÖSCH we are always pushing the limits. We manufacture highly pliable, thin-walled moulded parts with the tightest of tolerances based on your requirements.

How large can silicone injection moulded parts be?

Precision moulded parts, including micro-injected moulding, are not a problem for us. At LÖSCH we are always pushing the limits. We manufacture highly pliable, thin-walled moulded parts with the tightest of tolerances based on your requirements.

What are other benefits of liquid silicone rubber?

The challenges from our customers keep us growing. Nothing motivates us as much as a project which needs a solution for implementation. Our creed: Anything’s possible. Our employees are here to support you even with complex projects.

Why choose LÖSCH as your partner for liquid silicone injection moulding?

- Excellent chemical and physical properties

- Outstanding sealing properties

- Great design freedom with respect to industrial production

- Cosmetics

- High biocompatibility

- Durability

- Flexibility

- Temperature resistance

- Excellent damping

How many pieces are a small-scale series in injection moulded liquid silicone rubber?

- Silicone experts with years of experience

- Wide silicone processing range with a production environment tailored specifically for injection moulded liquid silicone rubber

- Optimal material selection combined with application-specific design modifications

- Sprueless

What are the typical ideal applications for liquid silicone rubber?

Whether it’s connectors in the automotive industry, bottle nipples or rain sensors – the applications for liquid silicone rubber (LSR) injection moulded parts are extremely vast. Here at LÖSCH we are always pioneering and offer solid know-how from our numerous projects for a variety of industries.

- Automotive (sensors, connectors, gaskets)

- Medical products (e.g. mouth pieces, medical nipples, etc.)

- Food industry (e.g. dosers, bottle nipples, etc.)

- Plumbing and household (e.g. gaskets, baking tins, etc.)

- Electrical and mechanical engineering (e.g. gaskets, O-rings, etc.)

- Sports and recreation (e.g. toys, sporting goods, etc.)

- Lighting technology (lenses, mixing rods, etc.)

What is LSR?

LSR is short for liquid silicone rubber.

What are the properties of liquid silicone rubber

- High temperature resistance to approx. +200 °C

- High cold resistance to approx. -40 °C whilst maintaining elasticity

- Excellent ageing stability

- Low compression set

- High non-shrinking property

- Wall fissures without compromising optics

- Undercuts can be shown through forced demoulding

- Safe for contact with blood

- Excellent skin tolerance

- Excellent extractable profile (lowest content of triggering substances)

- Suitable for all common sterilisation methods

- Tintable to various colours

What is liquid silicone rubber?

Liquid silicone rubbers are addition-curing silicone rubbers consisting of two components (catalyst and curer) which are kept in separate containers. This allows the curing process to start at precisely the desired moment. Separating them further has the advantage of significantly improving the supply availability and shelf life of the raw materials.

Contact us and tell us about your project. We look forward to an initial consultation without obligation.

+49 9874 507239-0

Free Project Analysis

Request your free, non-binding project analysis today